Rising pass rate: The product pass rate has increased to 99.99%, reducing over 2 million pieces of waste annually

Medical Solutions

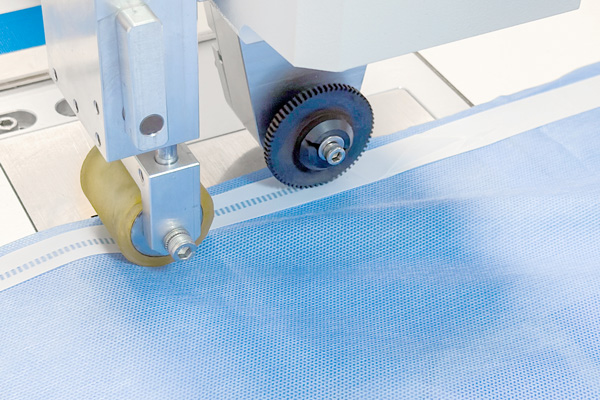

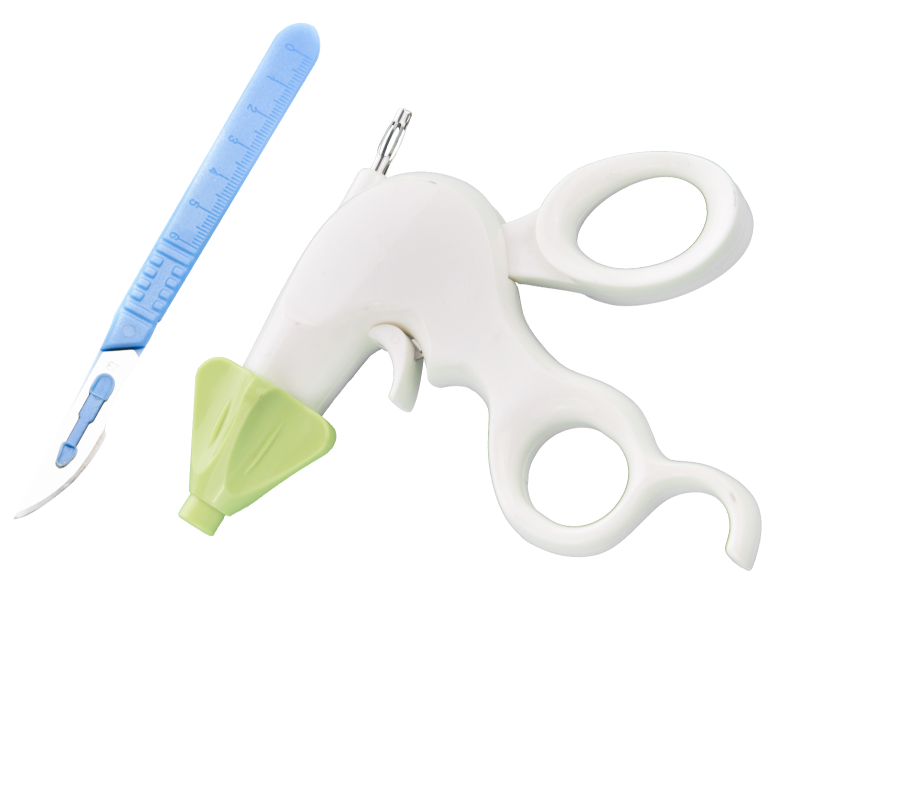

Medical grade ultrasonic welding

Lingke Ultrasonic Welding for Medical Products

Faced with the increasing precision requirements of medical devices, traditional connection processes have limitations such as pollution risks and low efficiency.

Lingke ultrasonic welding technology, with its advantages of cleanliness, safety, precision, firmness, and efficient traceability, has become an ideal choice in the medical manufacturing field.